From Scrap to Ingot

In the world of Die, Casting, Foundry, Ingot Making, Recycling, Mold, and Die-Making industries, the journey of metal begins with recycling and culminates in the production of high-quality ingots. Dynamo Furnaces, a leading melting and holding furnace manufacturer, plays a pivotal role in this transformation. In this article, we will explore the significance of metal recycling, the efficient melting of scrap metal with Dynamo Furnaces’ chip melting furnaces, and the subsequent casting of ingots. By understanding this journey, we can appreciate the environmental and economic benefits that Dynamo Furnaces brings to the table.

The Significance of Metal Recycling

Metal recycling holds immense importance in today’s industrial landscape. It not only helps conserve natural resources but also reduces energy consumption and greenhouse gas emissions. The recycling process involves collecting, sorting, shredding, and melting scrap metal to give it new life. Dynamo Furnaces recognizes the significance of metal recycling and provides efficient solutions for melting scrap metal.

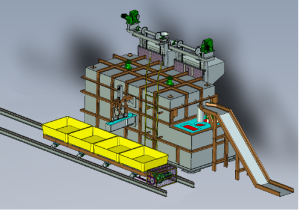

Efficient Scrap Metal Melting with Dynamo Furnaces

Chip melting furnaces offered by Dynamo Furnaces are designed to efficiently melt scrap metal. These furnaces are equipped with advanced technologies that optimize energy consumption and maximize productivity. With precise temperature control and robust insulation, Dynamo Furnaces’ chip-melting furnaces enable sustainable recycling practices. An anecdote worth mentioning is when a customer in the recycling industry sought Dynamo Furnaces’ expertise to enhance their metal recycling operations. By incorporating their chip melting furnace, the customer experienced a significant increase in throughput and improved energy efficiency, ultimately enhancing their bottom line.

Transformation into Molten Metal

The scrap metal, once melted, undergoes a transformative process, turning into molten metal. This critical step requires melting furnaces that can achieve precise temperature control while minimizing energy consumption. Dynamo Furnaces’ melting furnaces are designed to meet these specific requirements, delivering optimal melting conditions. Their advanced burner technology and efficient insulation contribute to reduced energy costs and enhanced melting performance. With Dynamo Furnaces’ melting furnaces, businesses can efficiently transform scrap metal into high-quality molten metal, ready for the next stage of the journey.

Casting Ingots: The Path to Reuse

The molten metal is then cast into ingots or bars, marking the final stage of the journey. Ingots serve as the foundation for various industrial applications, including Die, Casting, Foundry, Ingot Making, Recycling, Mold, and Die-Making processes. Dynamo Furnaces offers specialized melting and holding furnaces designed explicitly for ingot making. These furnaces ensure the production of high-quality ingots with precise temperature control and excellent metal purity.

Customization for Specific Requirements

Dynamo Furnaces understands that different industries have unique requirements when it comes to metal melting and ingot making. That’s why they offer customization options to meet these specific needs. Whether it’s die casting, foundry operations, or specialty alloy production, Dynamo Furnaces can tailor their furnaces to deliver optimal performance. Their expertise in custom engineering solutions has empowered businesses across industries to achieve their desired outcomes efficiently.

Conclusion

The journey of metal, from scrap to ingot, is a vital process that requires efficient recycling and melting solutions. Dynamo Furnaces plays a crucial role in this journey, offering chip-melting furnaces that optimize scrap metal recycling and specialized melting and holding furnaces for ingot production. By embracing sustainable practices and delivering customized solutions, Dynamo Furnaces has become a trusted partner for businesses in the Die, Casting, Foundry, Ingot Making, Recycling, Mold, and Die-Making industries. Choose Dynamo Furnaces to embark on the transformative journey of metal, ensuring sustainable operations and the production of high-quality ingots.

Helpful Resources: