Mini Stack Melting Furnace

GM-E Series

Our GM-E Series gas mini stack melting furnace, also known as mini shaft, or mini tower melter, has all the features and melting speed of our large central stack melting furnace, but has a much smaller footprint. This furnace is designed to be placed beside a die casting machine, or in any location where space is limited. It can also serve as a central melter for smaller dip out operations. This series features an automated charging elevator for simplified charging. Like all our furnaces, the GM-E Series is controlled by a PLC and a large color HMI touch screen which runs a sophisticated program that optimizes performance, operation, and efficiency. The GM-E Series is very competitively priced.

Overview

VIDEO

See What This Furnace Has to Offer.

The GM-E Series Mini stack melting furnaces are built solidly, very well insulated, and use only the finest quality components.

High Thermal Efficiency

BY DESIGN

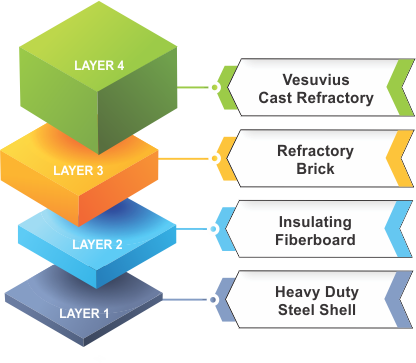

We Add Multiple Layers of Insulation.

The result is excellent efficiency which means a furnace which not only burns less gas, but is actually not dangerous to touch.

THICKER

INSULATION

We Add Way More Insulation to Our Furnaces Than Most Manufacturers.

The result is even greater efficiency and a solid, sturdy construction which is hard to beat.

Easy to Operate

INTERFACE

Greater Control - Means Greater Efficiency.

The GM-E Series Mini stack melting furnaces feature state-of-the-art PLC control with large color HMI screens with easy to read graphics - all at no extra charge. See in real time all furnace functions and change any setting on the fly. Now that's control.

CERAMIC

ALUMINUM DROSS FILTRATION

Comes Standard with All Models and Keeps Your Aluminum Clean.

Our ceramic foam filter can effectively remove and absorb large or small impurities in molten aluminum, improves the surface quality, and microstructure effectiveness. This ceramic filter is thermal shock resistant and improves purity and erosion resistance of the molten aluminum.

AUTOMATED

CHARGING

Eliminates Tedious Charging and Simplifies Operation.

The other end of this furnace features a shaft melter with an automatic elevator which has a tilting cart for ingots, returns and scrap. The carts are inserted at the bottom with various types of aluminum material and the cart travels up, the shaft melting lid is opened and the cart dumps the load, and returns to the bottom. The cart is pulled out and another full cart is loaded.

INFRARED

STACK LEVEL SENSOR

Optimized Shaft Filling.

This furnace features an infrared sensor which monitors the level of material in the melting shaft. Once the correct level is achieved a signal is sent to the elevator to sent the cart up with more material. The system ensures optimized filling for maximum performance.

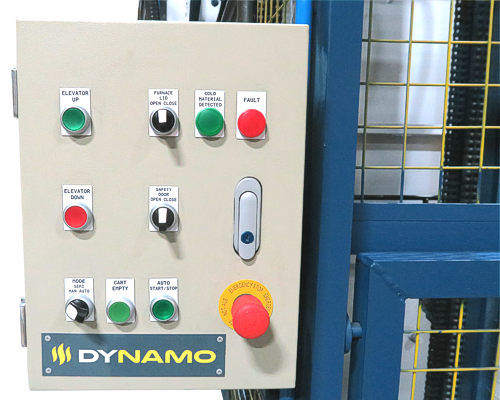

SHAFT ELEVATOR

CONTROL

Simplifies Elevator Loading.

All the controls needed to operate and load the shaft elevator with carts are on a separate panel located right on the elevator.

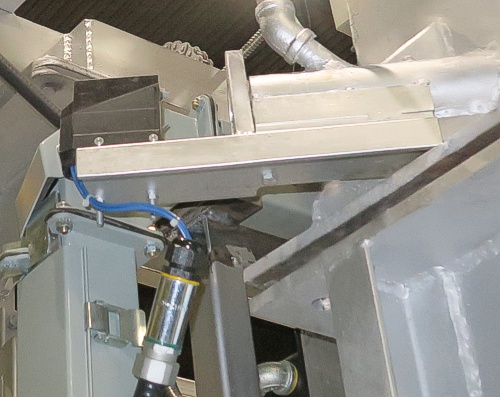

AIR

MANIFOLD

Complete System Included.

The furnaces comes with a dependable air manifold that is properly scaled for the pneumatic air cylinder which operates the shaft melting cover. Air is used also to keep the shaft level sensors clean and clear.

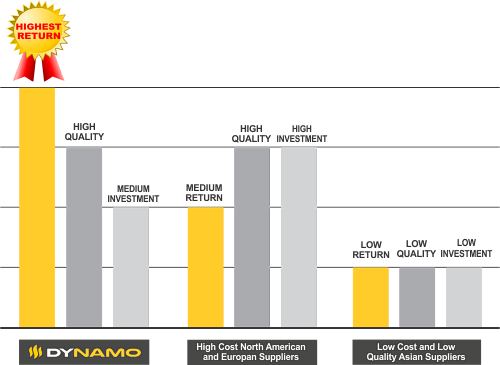

HIGHEST RETURN ON

INVESTMENT

We Give You More Furnace for Your Money.

To be competitive today’s economy requires that manufacturers run their operations more efficiently and cost effectively than ever before. We offer the highest ROI (return on investment) in the industry. Dynamo gives you high-quality products for a reasonable investment and with more features than any other company. Simply put, we give you the most for your money!

TWO SIDE

CLEANOUT DOORS

We Made Furnace Cleaning Easier.

The two side cleanout doors and the large pre-heat ramp door give the operator easy access to all parts of the furnace interior for easy cleaning. There are no blind spots to deal with. All this encourages regular furnace cleaning.

ARTICULATING

CLEANOUT DOOR PANEL

Simplifies Furnace Cleaning.

Our articulating cleanout door panel allows the opening and closing of both side cleanout doors individually with a clear view of both doors. The panel is located conveniently and can be pushed out of the way when not needed.

QUICK

CONNECT

Fast Onsite Connection.

Our quick connection plugs eliminate onsite wiring errors and allow for quick onsite furnace assembly and future maintenance. It is one of the little things that count and make our furnaces different.

CHOOSE YOUR

CONTROL SYSTEM

We Give You Options of PLC & HMI.

Select the control system that is best for you and easiest for your maintenance team.

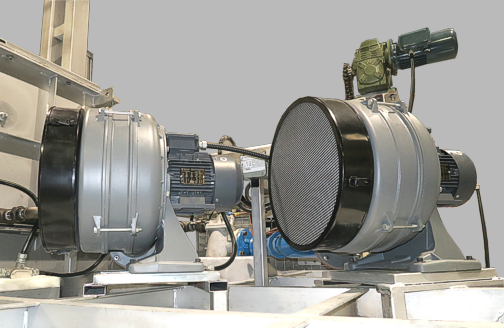

DUAL AIR

BLOWERS

Two are Better Than One.

Using double air blowers gives us more flexibility and precision in the amount of air available for the melting and holding chambers at any given time. When balanced correctly they increase the efficiency of the furnace and reduce running costs.

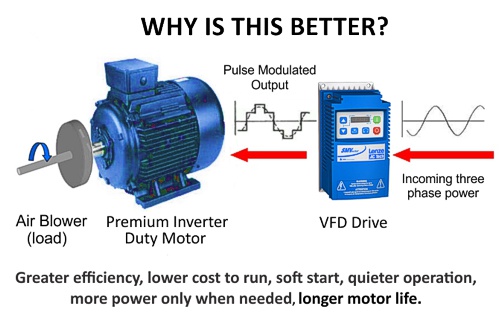

VFD DRIVE BLOWER

MOTORS

Better Efficiency and Lower Operating Cost.

Lots of air without control wastes a significant amount of energy. We use VFD Drives combined with Premium Inverter Duty Motors to give you greater RPM only when it is needed. All this translates into greater efficiency, lower operating costs, quieter operation, soft start and longer motor life. The advantage is clear. This is just one of the many ways we use to increase furnace efficiency, and reduce long term operating costs.

HIGH QUALITY

COMPONENTS

We Use Brand Name Components You Know and Already Use.

We use only the finest quality components that are open source and readily available locally in your area, or from our online parts store.

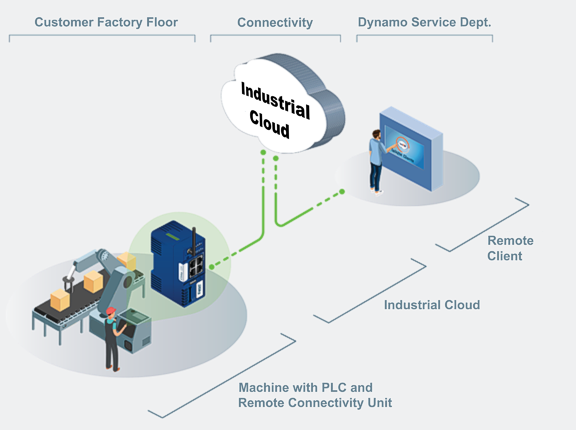

REMOTE

SERVICE

We Can Remotely Troubleshoot Your Furnace from Our Facility.

Our GM-E Series mini stack melting furnaces include a Remote Connectivity Unit which allows our furnace technicians to remotely check the performance of the furnace, make any needed changes to the program or HMI, or to troubleshoot it directly from our service center. The customer is only required to connect the unit to the Internet via an Ethernet cable. We handle the rest.

INDUSTRY 4.0

REMOTE MONITORING

Remotely Monitor Your Furnace Performance From Any Device.

As an option, all our furnaces are available with Industry 4.0 remote performance monitoring units which feature a custom dashboard. You can not only monitor furnace performance, but you can be notified before an issue occurs. Included are condition based maintenance reminders and shift performance statistics. Minimize impact of emergencies and maximize furnace uptime, and productivity. See what is going on with the furnace and your production from any device, anywhere in the world.

Eight Standard

SIZES

Flexible Range of Applications.

Available from a small 770 lbs holding capacity all the way to 4400 lbs, the GM-E Series mini tower melting furnaces allow for a wide range of applications. NOTE: Higher melting rates are available by request.

| Standard | US / Imperial (Al) | Metric (Al) | ||

| Model | Holding | Melting/h | Holding | Melting/h |

| GM-E-770 | 770 lb | 220 lb | 350 kg | 109 kg |

| GM-E-1100 | 1100 lb | 330 lb | 500 kg | 155 kg |

| GM-E-1400 | 1400 lb | 440 lb | 650 kg | 200 kg |

| GM-E-1760 | 1760 lb | 550 lb | 800 kg | 250 kg |

| GM-E-2050 | 2050 lb | 660 lb | 950 kg | 300 kg |

| GM-E-2600 | 2600 lb | 880 lb | 1200 kg | 400 kg |

| GM-E-3300 | 3300 lb | 1100 lb | 1500 kg | 500 kg |

| GM-E-4400 | 4400 lb | 1650 lb | 2000 kg | 750 kg |

DO YOU NEED

BIGGER CAPACITY?

Be Sure to Check Out of Full Size Central Melting Furnaces.

We have a full line of larger holding and melting capacity furnaces with the same great features and options.

SHOWROOM ADDRESS

200 Beverly St, Unit 5, Cambridge, ON

Phone

+519-624-9987

contact@dynamofurnaces.com