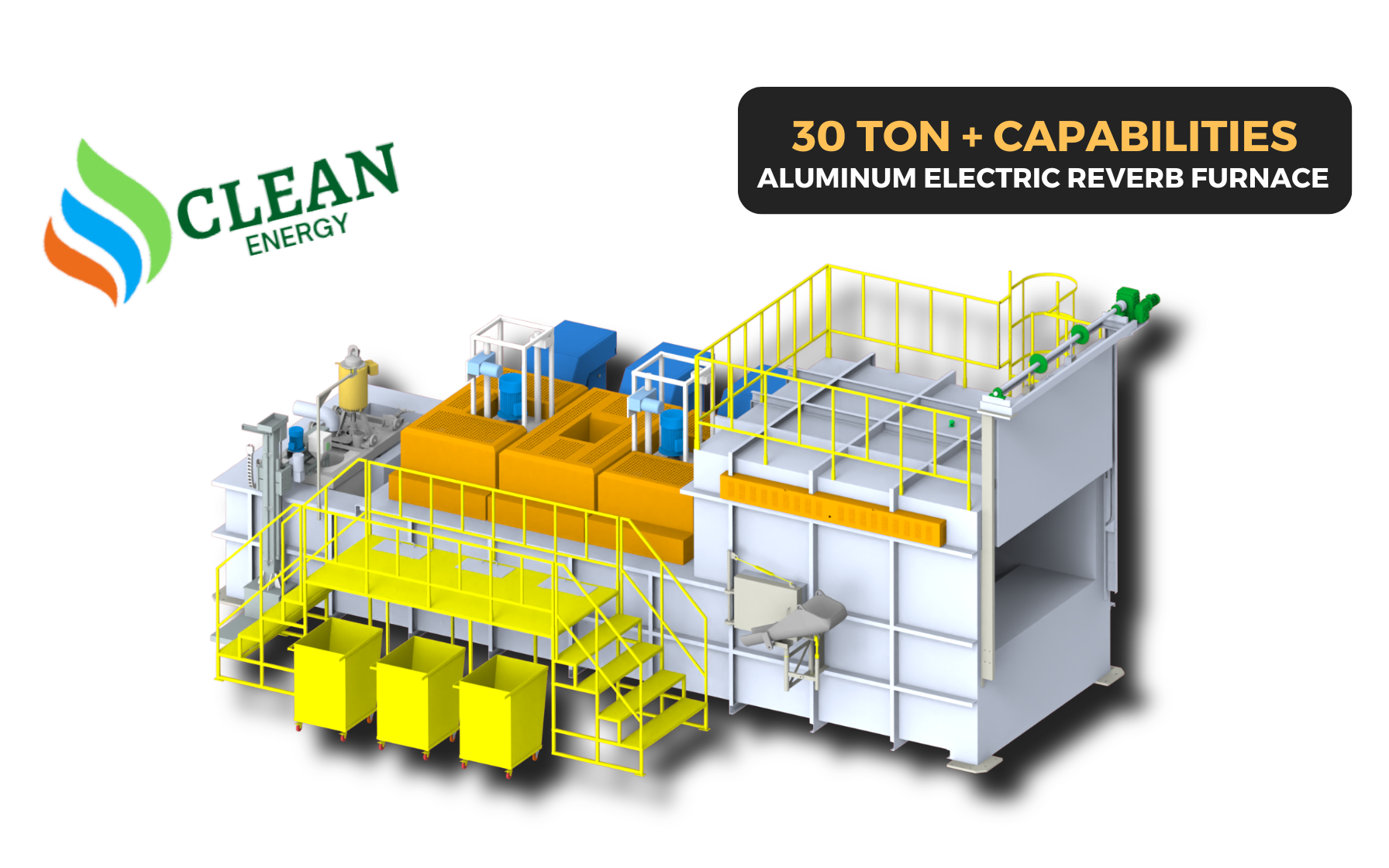

ALUMINUM ELECTRIC REVERB

MELTING & HOLDING FURNACES

The ION MELTER, presents a groundbreaking solution to the pervasive problem of oxidative melt loss. This aluminum electric melting and holding furnace is designed with advanced technologies that target the reduction of oxidative melt loss. This improvement enhances efficiency, reduces energy consumption, and lowers production costs, thereby promoting more environmentally friendly manufacturing practices.

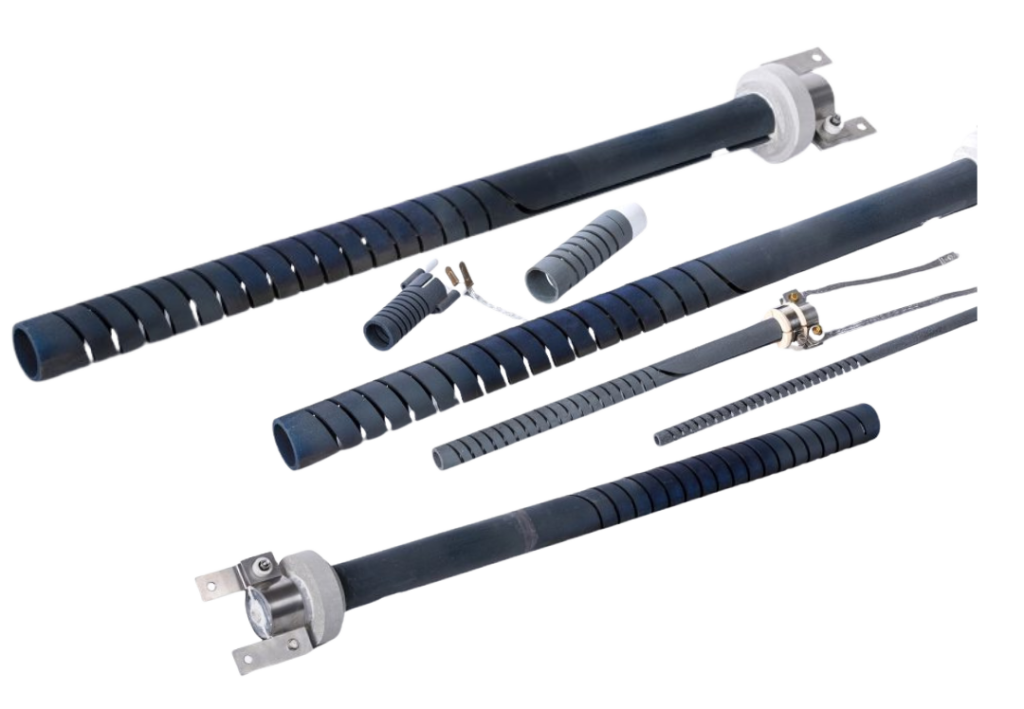

THE BENEFITS OF

IMMERSION HEATERS

ION MELTER INNOVATION

The use of a new generation of innovative immersion heaters in aluminum processing significantly enhances energy efficiency and reduces oxidative melt loss. By directly transferring heat to the material, immersion heaters minimize exposure to air, thus curtailing the formation of dross—an oxide layer that represents material loss. This direct heating method not only accelerates melting processes but also promotes uniform temperature distribution, further mitigating oxidation.

The result is a more efficient, cost-effective, and environmentally friendly production process, emphasizing the crucial role of immersion heaters in modern aluminum manufacturing.

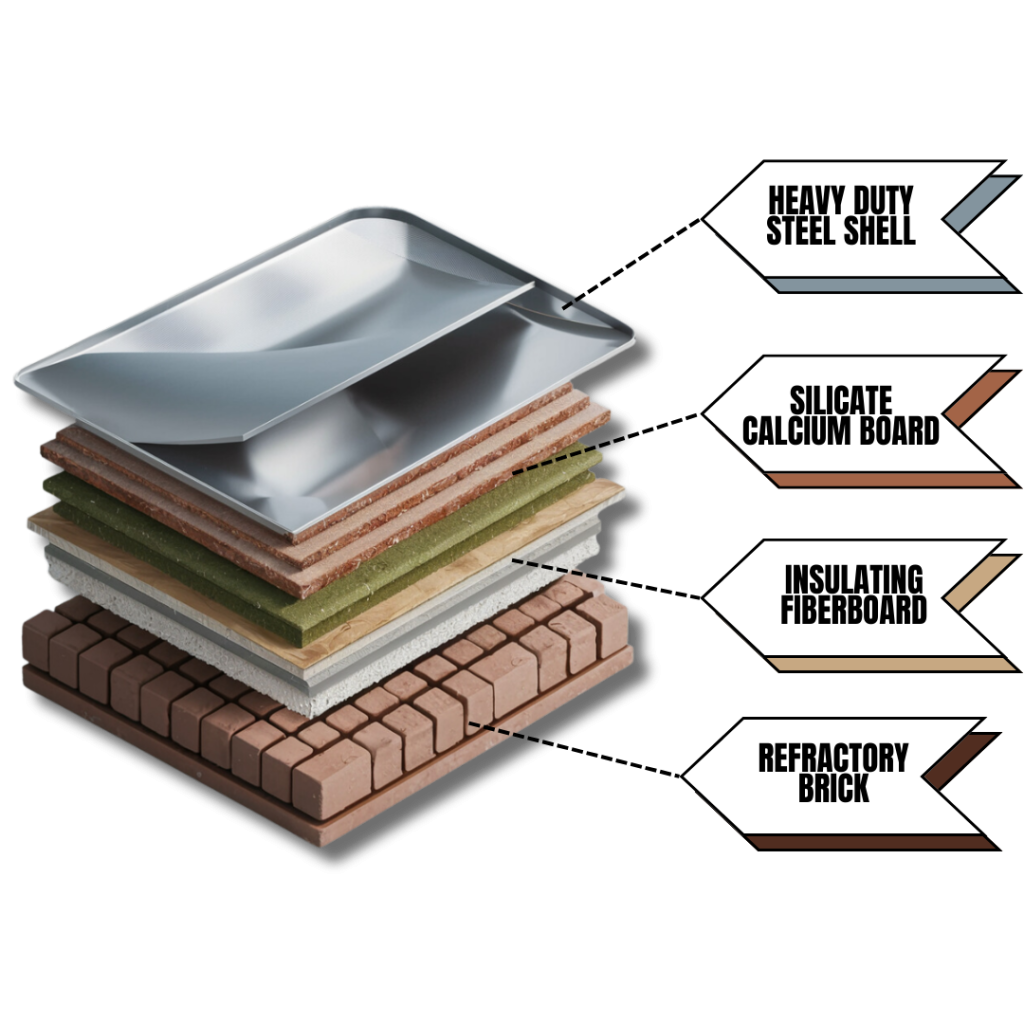

Alta eficiencia térmica

POR DISEÑO

Añadimos varias capas de aislamiento.

Adding more layers of insulation results in excellent efficiency which means a furnace which not only burns less gas, but is actually not dangerous to touch.

Fácil de manejar

INTERFAZ

Mayor control: mayor eficacia.

The EM-L Series electric resistance melting furnaces feature state-of-the-art PLC control with large color HMI screens with easy-to-read graphics - all at no extra charge. See in real time all furnace functions and change any setting on the fly. Now that's control.

ELIGE TU

SISTEMA DE CONTROL

Le damos opciones de PLC y HMI.

Seleccione el sistema de control que más le convenga y el más sencillo para su equipo de mantenimiento.

ENHANCEMENT WITH

THYRISTOR TECHNOLOGY

Eco-friendly and Efficient Aluminum Production.

Thyristors play a key role in optimizing the ION MELTER, providing precise electrical power control. This advanced technology ensures energy is utilized more efficiently, significantly reducing consumption and operational costs. Their robustness and reliability not only enhance the melter's performance but also extend its lifespan, making it a sustainable and cost-effective solution for aluminum melting processes.

DIRECCIÓN DE LA SALA DE EXPOSICIONES

200 Beverly St, Unidad 5, Cambridge, ON

Teléfono

+519-624-9987

Correo electrónico

contact@dynamofurnaces.com